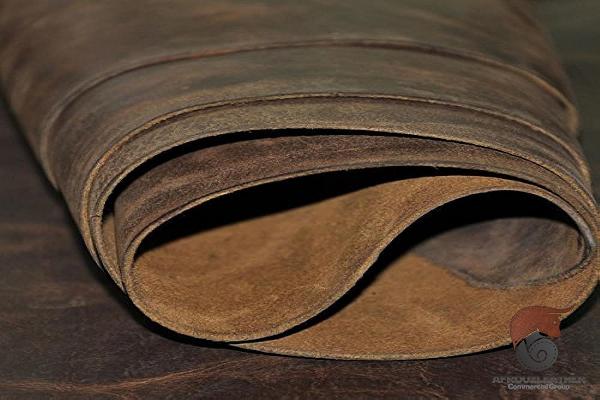

Leather has been an indispensable part of human history, valued for its durability, strength, and timeless beauty. Pure leather sheets, also known as leather hides or skins, are a versatile material that finds applications in various industries, including fashion, automotive, furniture, and interior design. This article aims to delve into the world of pure leather sheets, examining their characteristics, production process, and diverse range of uses. Characteristics of Pure Leather Sheets: Pure leather sheets are derived from the hide or skin of animals, typically cattle, sheep, goats, or pigs. The quality and characteristics of the leather depend on numerous factors, including the type of animal, the tanning process, and the grain used. Some key characteristics of pure leather sheets include: 1. Durability: Leather is renowned for its exceptional durability, making it resistant to wear and tear, and capable of withstanding the test of time. 2. Softness and Suppleness: Compared to other materials, leather sheets possess a unique softness and suppleness that adds to their appeal, making them incredibly comfortable to touch and handle.

leather

3. Breathability: Leather is a natural material that allows for air circulation, making it breathable, which can be particularly beneficial in fashion items or furniture. 4. Water Resistance: Pure leather sheets have inherent water resistance that prevents immediate penetration by water. However, they are not entirely waterproof, and extended exposure to moisture may cause damage. 5. Grain Variations: Leather sheets exhibit various grain types, such as full grain, top grain, corrected grain, or split grain. Each grain type has distinct characteristics that affect the overall appearance and quality of the leather. Production Process of Pure Leather Sheets: The production of pure leather sheets involves several stages, including: 1. Animal Slaughter: The initial step in the leather production process involves the careful selection, slaughtering, and skinning of animals to obtain the hides or skins. 2. Preservation and Cleaning: After skinning, the hides or skins are preserved through salting or chilling to prevent decay. They are then cleaned to remove any muscle tissues, fats, or blood residues. 3. Hair Removal: In order to transform hides or skins into leather, hair removal is necessary. This can be accomplished through either a mechanical process or a chemical treatment involving lime and other chemicals.

3. Breathability: Leather is a natural material that allows for air circulation, making it breathable, which can be particularly beneficial in fashion items or furniture. 4. Water Resistance: Pure leather sheets have inherent water resistance that prevents immediate penetration by water. However, they are not entirely waterproof, and extended exposure to moisture may cause damage. 5. Grain Variations: Leather sheets exhibit various grain types, such as full grain, top grain, corrected grain, or split grain. Each grain type has distinct characteristics that affect the overall appearance and quality of the leather. Production Process of Pure Leather Sheets: The production of pure leather sheets involves several stages, including: 1. Animal Slaughter: The initial step in the leather production process involves the careful selection, slaughtering, and skinning of animals to obtain the hides or skins. 2. Preservation and Cleaning: After skinning, the hides or skins are preserved through salting or chilling to prevent decay. They are then cleaned to remove any muscle tissues, fats, or blood residues. 3. Hair Removal: In order to transform hides or skins into leather, hair removal is necessary. This can be accomplished through either a mechanical process or a chemical treatment involving lime and other chemicals.

Specifications of leather

4. Tanning: Tanning is a crucial process that preserves the leather and imparts desired characteristics such as flexibility, color, and resistance to decay. There are two main methods of tanning: vegetable tanning and chrome tanning. 5. Finishing: Once tanning is complete, additional finishing processes may be conducted to enhance texture, color, or add protective coatings to the leather surface. Uses of Pure Leather Sheets: The versatility and attractiveness of pure leather sheets make them a desirable material for a wide range of applications. Some primary uses of pure leather sheets include: 1. Fashion Industry: Leather sheets are highly sought after in fashion, serving as the primary material for designing luxurious and stylish garments, shoes, accessories, and bags. The flexibility and durability of leather make it an excellent choice for creating high-quality, long-lasting products. 2. Automotive Industry: Leather sheets are commonly used in automobile interiors, including seats, steering wheels, and dashboards. Leather upholstery adds a touch of luxury and comfort while being durable and easy to clean. 3. Furniture and Interior Design: Leather sheets are widely used in the furniture industry to create luxurious sofas, chairs, ottomans, and headboards. Leather upholstery not only adds an element of sophistication but also offers durability and easy maintenance.

4. Tanning: Tanning is a crucial process that preserves the leather and imparts desired characteristics such as flexibility, color, and resistance to decay. There are two main methods of tanning: vegetable tanning and chrome tanning. 5. Finishing: Once tanning is complete, additional finishing processes may be conducted to enhance texture, color, or add protective coatings to the leather surface. Uses of Pure Leather Sheets: The versatility and attractiveness of pure leather sheets make them a desirable material for a wide range of applications. Some primary uses of pure leather sheets include: 1. Fashion Industry: Leather sheets are highly sought after in fashion, serving as the primary material for designing luxurious and stylish garments, shoes, accessories, and bags. The flexibility and durability of leather make it an excellent choice for creating high-quality, long-lasting products. 2. Automotive Industry: Leather sheets are commonly used in automobile interiors, including seats, steering wheels, and dashboards. Leather upholstery adds a touch of luxury and comfort while being durable and easy to clean. 3. Furniture and Interior Design: Leather sheets are widely used in the furniture industry to create luxurious sofas, chairs, ottomans, and headboards. Leather upholstery not only adds an element of sophistication but also offers durability and easy maintenance.

buy leather

4. Sports Industry: Leather sheets find applications in the sports industry, particularly for manufacturing quality sporting goods such as gloves, balls, and athletic footwear. 5. Accessories and Leather Goods: Leather sheets are also utilized in the production of accessories like wallets, belts, phone cases, and watch straps, exuding elegance and longevity with their natural grains. 6. Arts and Crafts: Leather sheets are favored by artists and craftsmen due to their ability to be tooled, embossed, and dyed. The malleability of leather allows for the creation and customization of intricate designs, making it a popular choice for specialized crafts such as bookbinding, upholstery, and leatherworking. Sustainability and Ethics: Leather production raises concerns regarding sustainability and ethical practices. The use of animal hides to produce leather is ultimately a byproduct of the meat industry. However, it is essential for manufacturers and consumers to ensure that leather is sourced from reputable suppliers who adhere to strict regulations regarding animal welfare and sustainability practices. Conclusion: Pure leather sheets have been esteemed for centuries for their durability, versatility, and luxurious appeal. As a natural material with inherent strength and flexibility, leather finds applications in various industries, ranging from fashion and automotive to interior design and crafts. Understanding the characteristics and production process of pure leather sheets contributes to a deeper appreciation of this timeless material and its numerous applications in modern society.

4. Sports Industry: Leather sheets find applications in the sports industry, particularly for manufacturing quality sporting goods such as gloves, balls, and athletic footwear. 5. Accessories and Leather Goods: Leather sheets are also utilized in the production of accessories like wallets, belts, phone cases, and watch straps, exuding elegance and longevity with their natural grains. 6. Arts and Crafts: Leather sheets are favored by artists and craftsmen due to their ability to be tooled, embossed, and dyed. The malleability of leather allows for the creation and customization of intricate designs, making it a popular choice for specialized crafts such as bookbinding, upholstery, and leatherworking. Sustainability and Ethics: Leather production raises concerns regarding sustainability and ethical practices. The use of animal hides to produce leather is ultimately a byproduct of the meat industry. However, it is essential for manufacturers and consumers to ensure that leather is sourced from reputable suppliers who adhere to strict regulations regarding animal welfare and sustainability practices. Conclusion: Pure leather sheets have been esteemed for centuries for their durability, versatility, and luxurious appeal. As a natural material with inherent strength and flexibility, leather finds applications in various industries, ranging from fashion and automotive to interior design and crafts. Understanding the characteristics and production process of pure leather sheets contributes to a deeper appreciation of this timeless material and its numerous applications in modern society.

Your comment submitted.