In the world of fashion and manufacturing, genuine leather remains a timeless and highly coveted material. Known for its durability, texture, and timeless appeal, genuine leather is widely used in the production of various products like clothing, footwear, furniture, bags, and accessories. Behind the scenes, the production of genuine leather materials involves a complex and meticulous process that begins with the sourcing of raw hides and ends with the creation of high-quality finished goods. Structure: 1. Sourcing and Selection of Raw Hides 2. Pre-Treatment and Preservation of Hides 3. Tanning Process 4. Finishing Techniques 5. Quality Control Measures 6. Ethical Considerations in Genuine Leather Production 7. Future Trends and Challenges 1. Sourcing and Selection of Raw Hides: Genuine leather production starts with the careful selection and sourcing of high-quality raw hides. These hides mainly come from domesticated animals such as cattle, sheep, goats, and pigs.

leather

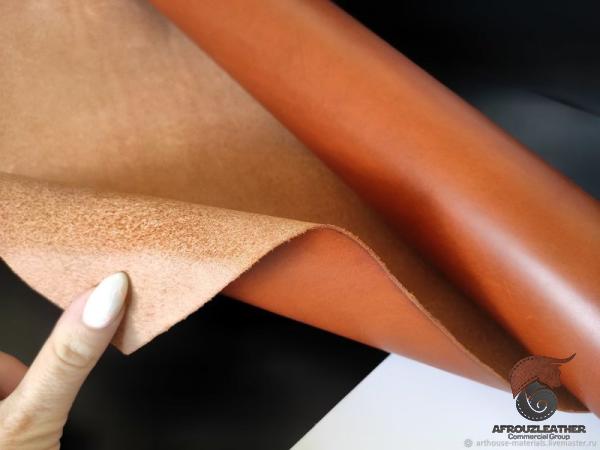

Factors considered during selection include the age, health, and breed of the animals, as well as the environment they were raised in. The quality and characteristics of the raw hides play a crucial role in determining the resulting leather’s end use and market value. 2. Pre-Treatment and Preservation of Hides: After sourcing, the raw hides undergo various pre-treatment processes to remove unwanted substances and preserve their quality. This involves the removal of hair, flesh, and fatty tissues through a process known as dehairing and fleshing. The preservation of hides is typically achieved through salting or refrigeration, which inhibits bacterial growth and prevents decay until they can be processed further. 3. Tanning Process: The tanning process is the heart of genuine leather material production and involves treating the prepared hides with tannins to transform them into stable, long-lasting leather. Tanning can be done through various methods, but the most common are vegetable tanning, chrome tanning, and combination tanning. Vegetable tanning, the oldest method, uses plant-based tannins derived from sources like oak bark, quebracho, or mimosa to create a soft, breathable, and environmentally friendly leather. Chrome tanning, on the other hand, utilizes chromium salts, resulting in a softer, more flexible leather suitable for a wide range of products. Combination tanning combines both vegetable and chrome tanning to achieve specific characteristics desired in the finished leather.

Factors considered during selection include the age, health, and breed of the animals, as well as the environment they were raised in. The quality and characteristics of the raw hides play a crucial role in determining the resulting leather’s end use and market value. 2. Pre-Treatment and Preservation of Hides: After sourcing, the raw hides undergo various pre-treatment processes to remove unwanted substances and preserve their quality. This involves the removal of hair, flesh, and fatty tissues through a process known as dehairing and fleshing. The preservation of hides is typically achieved through salting or refrigeration, which inhibits bacterial growth and prevents decay until they can be processed further. 3. Tanning Process: The tanning process is the heart of genuine leather material production and involves treating the prepared hides with tannins to transform them into stable, long-lasting leather. Tanning can be done through various methods, but the most common are vegetable tanning, chrome tanning, and combination tanning. Vegetable tanning, the oldest method, uses plant-based tannins derived from sources like oak bark, quebracho, or mimosa to create a soft, breathable, and environmentally friendly leather. Chrome tanning, on the other hand, utilizes chromium salts, resulting in a softer, more flexible leather suitable for a wide range of products. Combination tanning combines both vegetable and chrome tanning to achieve specific characteristics desired in the finished leather.

Specifications of leather

4. Finishing Techniques: After tanning, the leather is ready for various finishing treatments to enhance its appearance and end-use properties. These treatments include dyeing, buffing, polishing, embossing, and applying protective coatings such as waxes or oils. Finishing techniques aim to give leather its desired color, texture, and surface characteristics, making it more appealing to consumers and suitable for different applications. 5. Quality Control Measures: Ensuring the quality and consistency of genuine leather material production is of utmost importance. Quality control measures are implemented throughout the entire manufacturing process. Inspection and grading are carried out to assess the quality of raw hides, monitor the tanning process, and evaluate the finished leather’s physical and aesthetic properties. Quality control teams also check for any defects or blemishes that might affect the material’s performance and marketability. 6. Ethical Considerations in Genuine Leather Production: With growing concerns about animal welfare and the environmental impact of the leather industry, ethical considerations have become increasingly important in genuine leather production. Many manufacturers now prioritize sourcing hides from areas where animal welfare regulations are in place.

4. Finishing Techniques: After tanning, the leather is ready for various finishing treatments to enhance its appearance and end-use properties. These treatments include dyeing, buffing, polishing, embossing, and applying protective coatings such as waxes or oils. Finishing techniques aim to give leather its desired color, texture, and surface characteristics, making it more appealing to consumers and suitable for different applications. 5. Quality Control Measures: Ensuring the quality and consistency of genuine leather material production is of utmost importance. Quality control measures are implemented throughout the entire manufacturing process. Inspection and grading are carried out to assess the quality of raw hides, monitor the tanning process, and evaluate the finished leather’s physical and aesthetic properties. Quality control teams also check for any defects or blemishes that might affect the material’s performance and marketability. 6. Ethical Considerations in Genuine Leather Production: With growing concerns about animal welfare and the environmental impact of the leather industry, ethical considerations have become increasingly important in genuine leather production. Many manufacturers now prioritize sourcing hides from areas where animal welfare regulations are in place.

buy leather

Additionally, sustainable practices such as the use of vegetable-based tanning agents, water recycling systems, and waste reduction initiatives are being adopted to minimize environmental impact and address ethical concerns. 7. Future Trends and Challenges: As technology advances and consumer preferences evolve, the genuine leather industry faces various challenges and opportunities. One notable trend is the growing demand for eco-friendly and ethically sourced leather alternatives, such as vegetable-tanned leather or leather made from innovative materials like plant-based fibers. The development of new tanning methods that reduce water consumption and chemical usage is also gaining momentum. Balancing these emerging trends with the timeless appeal of genuine leather will prove crucial for the industry’s future success. Conclusion: Genuine leather material factories play a vital role in meeting the demand for high-quality and durable leather products. The intricate process of sourcing, treating, and finishing raw hides ensures the production of genuine leather materials that are both visually appealing and functional. As consumer preferences shift towards sustainability and ethical practices, the genuine leather industry will need to adapt to meet these demands while preserving the time-honored qualities that have made genuine leather an enduring luxury material.

Additionally, sustainable practices such as the use of vegetable-based tanning agents, water recycling systems, and waste reduction initiatives are being adopted to minimize environmental impact and address ethical concerns. 7. Future Trends and Challenges: As technology advances and consumer preferences evolve, the genuine leather industry faces various challenges and opportunities. One notable trend is the growing demand for eco-friendly and ethically sourced leather alternatives, such as vegetable-tanned leather or leather made from innovative materials like plant-based fibers. The development of new tanning methods that reduce water consumption and chemical usage is also gaining momentum. Balancing these emerging trends with the timeless appeal of genuine leather will prove crucial for the industry’s future success. Conclusion: Genuine leather material factories play a vital role in meeting the demand for high-quality and durable leather products. The intricate process of sourcing, treating, and finishing raw hides ensures the production of genuine leather materials that are both visually appealing and functional. As consumer preferences shift towards sustainability and ethical practices, the genuine leather industry will need to adapt to meet these demands while preserving the time-honored qualities that have made genuine leather an enduring luxury material.

Your comment submitted.